Brand: CNSME

Model Number: SM/200E

Certificate: CE/ISO

Place of Origin: Hebei,China

Minimum Order Quantity: 1set

Delivery Time: 7-15 working days

Payment Terms: T/T, L/C

Supply Ability: 30 Sets per Month

Packaging Details: Standard export packaging

Payment Terms: T/T,Western Union

Supply Ability: 100 Sets per Month

Packaging Details: Standard export packaging

▶Our horizontal slurry pumps are designed for heavy duty applications such as mining, minerals processing, mill discharge, power plants, tailings and other industrial applications, for maximum abrasion, erosion and corrosion resistance.

▶The pumps are in a wide range of sizes, available with both high chrome and ruber wearing parts. Components like impeller and volute come in a range of hard metal types and elastomer to suit the specific application.

▶Different shaft seal types are available to suit every requirement, including gland packing seal, expeller seal and mechanical seal.

▶Our metal lined slurry pumps are designed for heavy duty industrial applications, to handle the most arduous slurries.

▶Wear resistant cast alloys are used for slurry pump liners and impellers where conditions are not suited to rubber, such as with coarse or sharp edged particles, or on duties having high impeller peripheral velocities or high operating temperatures.

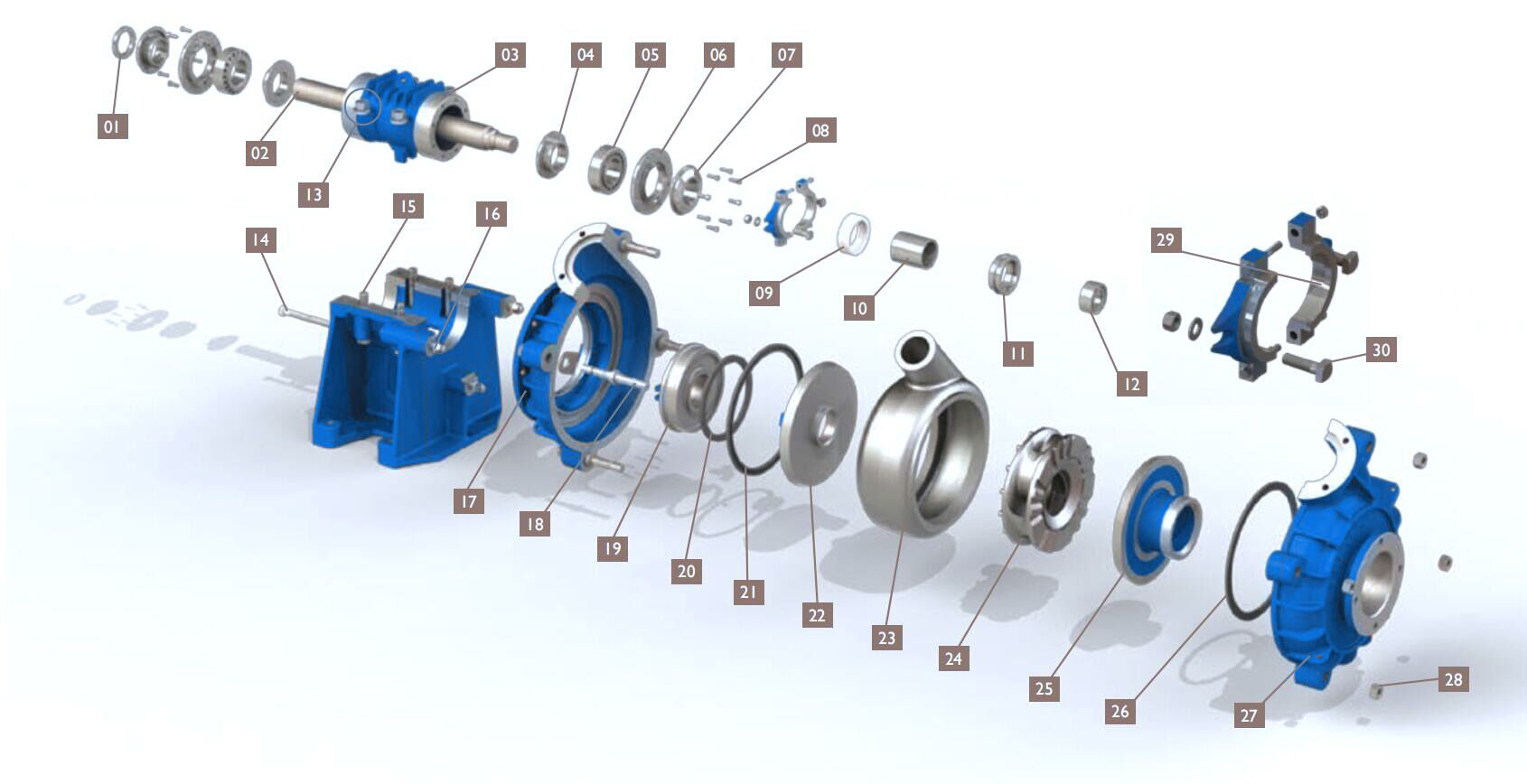

Pump Structure:

01. Labyrinth Lock Nut 02. Shaft 03. Bearing Housing 04. Grease Retainer 05. Bearings 06. End Cover 07. Labyrinth 08. End Cover Screw Set

09. Gland Packing 10. Shaft Sleeve 11. Lantern Restrictor 12. Shaft Spacer 13. Clamp Washer 14. Adjusting Screw 15. Clamp Bolt

16. Frame Plate Stud 17. Frame Plate 18. Cover Plate Bolt 19. Stuffing Box 20. Seal 21. Volute Seal 22. Frame Plate Liner Insert 23. Volute Liner

24. Impeller 25. Throatbush 26. Volute Seal 27. Cover Plate 28. Cover Plate Nut 29. Gland Assembly 30. Gland Bolt

Specifications:

| Pump Model | S×D (inch) | Allowable Max. Power (kw) | Material | Clear Water Performance | Impeller | ||||||

| Capacity Q | Head H(m) | Speed n(r/min) | Max.Eff. η% | NPSH (m) | No. of Vanes | Vane Dia. (mm) | |||||

| Impeller | m3/h | l/s | |||||||||

| SM/200E | 10×8 | 120 | Meral | 666-1440 | 185-400 | 14-60 | 600-1100 | 73 | 4-10 | 5 | 549 |

| SMR/200E | 10×8 | 120 | Rubber | 360-1080 | 100-300 | 10-40 | 500-900 | 79 | 3-9 | 549 | |

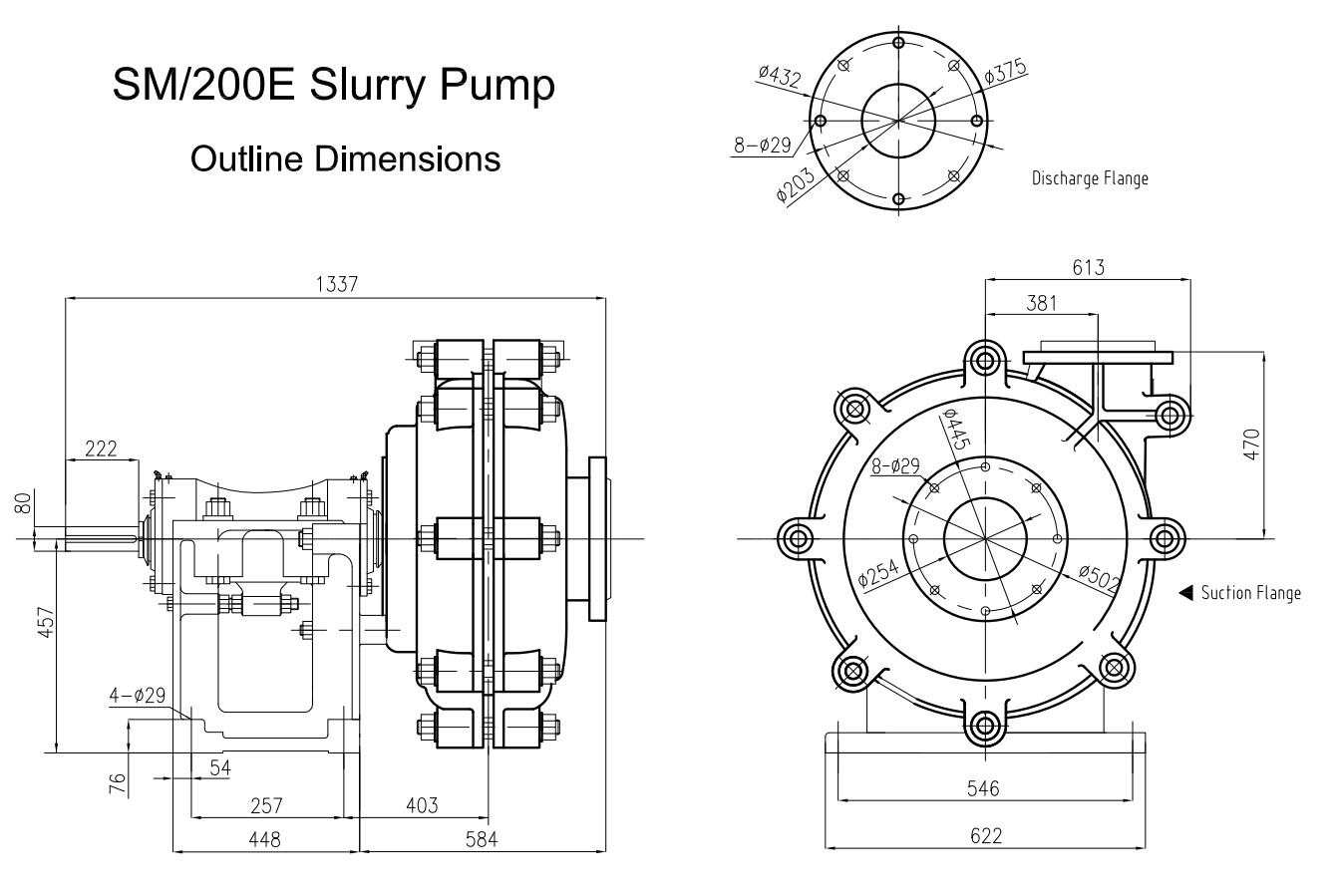

Outline Dimensions:

Applications:

Process Pumps

Mill Discharge

Medium to Low Pressure Tailings